This is the story of an entrepreneur and his family, and all those who in one way or another have collaborated to allow this family company to continue its success and good work.

In 1988, José Pla was a renowned professional in the then thriving textile industry of the Valencian region of La Vall d’Albaida. He became a father two weeks before going to the commercial registry to register Trenzados José Pla S.L., planning to begin the current activity.

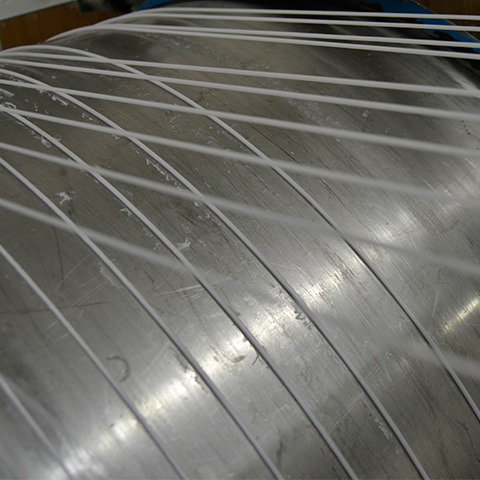

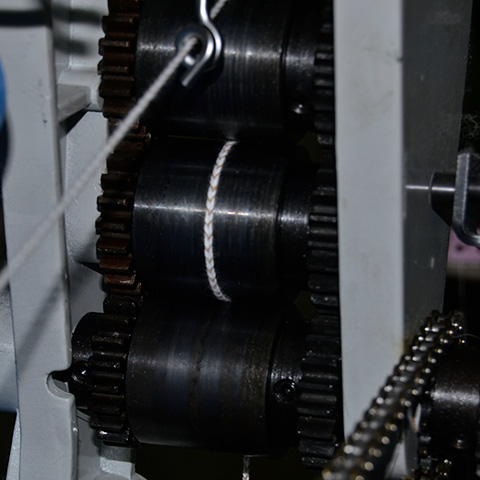

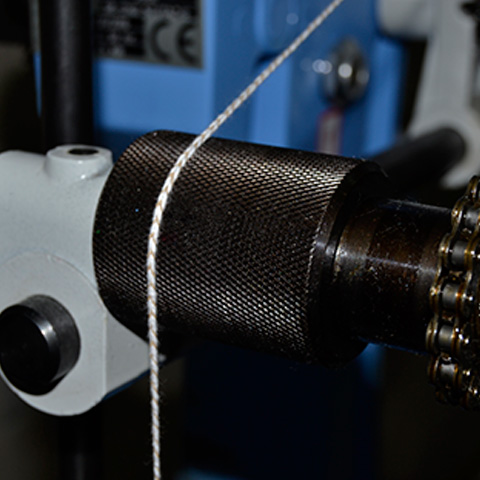

Until then, along with other colleagues, he had worked in manufacturing textiles for shoelaces. Shortly afterwards, other colleagues established a candle factory, and he was their supplier of wicks and tapers. A new member of the family and a new activity ahead posed a challenge. They say that this builds character.

THE PILLARS OF OUR WORK

QUALITY

INNOVATION

SERVICE

Exporter

Only four years later, the first order destined for abroad left the factory. First there were small orders, where candle factories could check the quality of the braids, and then larger orders of wicks; first to the LATAM market led by Mexico, then France, England, Italy, Germany, etc. The European market was there. José Pla notes that “One of the main values of manufacturers of this country appreciated abroad is the reliability and quality of the product”. Fulfilling the best product standards and order dates has allowed the company to enter the global market. “Nothing has been easy, but good work leads to success”.

Innovation – the key to success

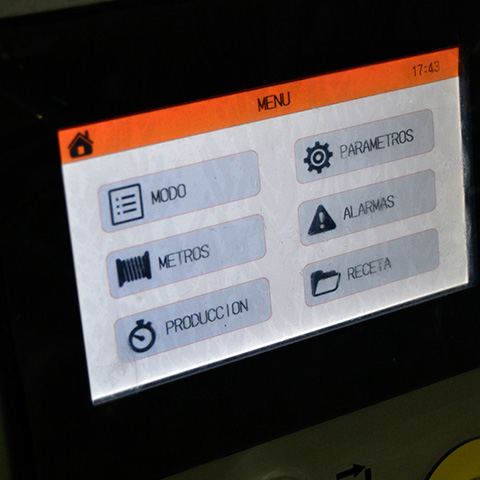

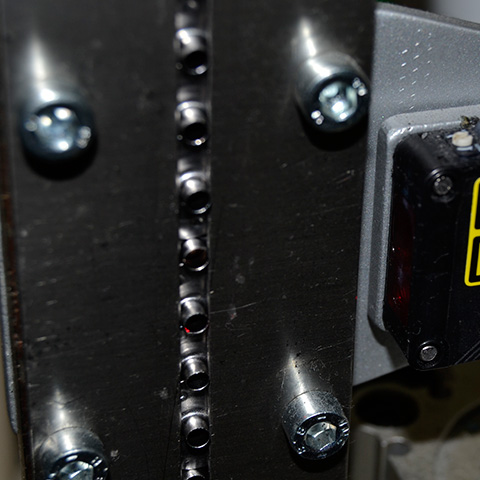

One may think that in such a traditional manufacturing sector there is no place for new innovations; but this assumption is wrong. There are multiple factors which affect a product from the start of its production until it reaches its final destination. In the case of Trenzados José Pla S.L., this innovation came from packaging and logistics. While everything had been invented in the manufacturing process, in logistics there was room for improvement. This improvement was made, with reduced costs and efficient management. “In the mind of the entrepreneur there is always room for improvement”.

The challenge of the future

The company has not lost its family aspect, and will remain the same in the future, transferring knowledge and experience, as well as providing new ideas and momentum – a combination that leads to good results. With regard to the wicks and tapers, the future will be committed to creating an increasingly efficient product, giving it a more environmentally friendly component, and ensuring that the product is of the greatest quality, created with natural raw materials.